Maxcon Fire Protection Sdn.Bhd is established and aim business to be one of the pioneer at Fire fighting system & Fire Safety project. In combination with the experience of a director who has served for several years in the field of fire safety enforcement in the Malaysian Fire and Rescue Department (BOMBA), we confidently could give guidelines and provide the latest technology & equipment which are suitable to the authority requirement.

FIRE ALARM SYSTEM

XXXXXXXXXXXXXX

A Conventional Fire Alarm System groups detectors into zones, so when an alarm triggers, the panel shows the zone but not the exact spot. It’s simple, reliable, and cost-effective — perfect for smaller buildings.

An Addressable Fire Alarm System takes it further by giving each device a unique address. This lets the panel pinpoint the exact detector in alarm, speeding up response and evacuation. Ideal for large, complex sites like hospitals, airports, and high-rises.

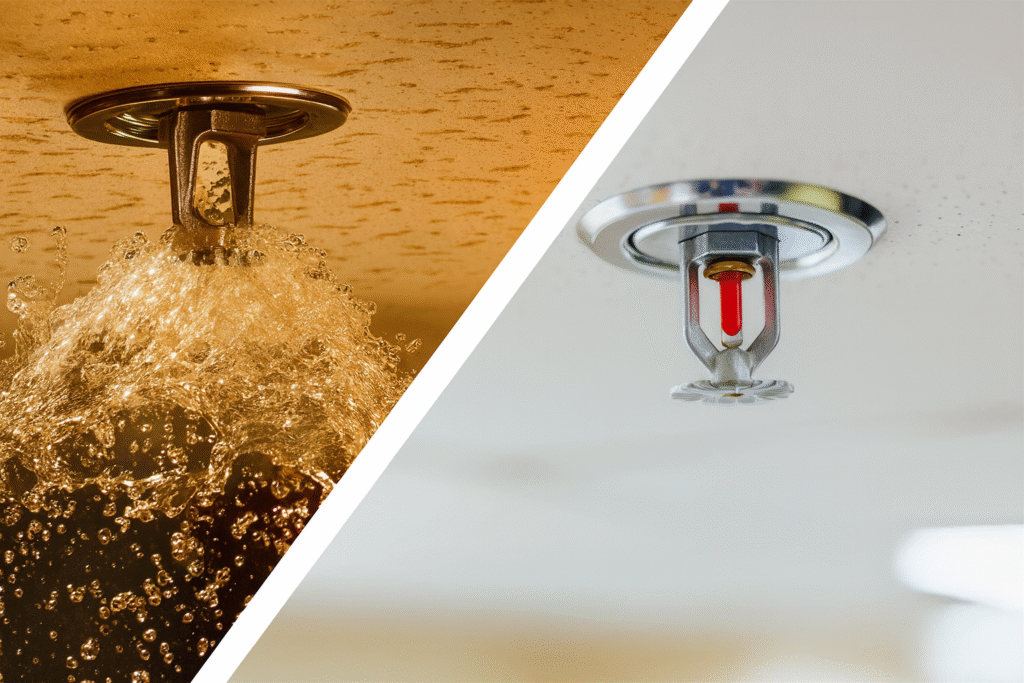

FIRE SPRINKLER HEAD

The frontline defense in automatic fire suppression

A fire sprinkler head is the outlet of an automatic sprinkler system, designed to detect heat and release water to control fires. It contains a heat-sensitive bulb or link that activates when temperatures rise, releasing water through that single head—not all at once as often believed.

Types include pendant (ceiling), upright (open ceilings), sidewall (wall-mounted), and concealed (aesthetic spaces). Quick-response heads are common in homes and schools, while standard-response types serve industrial settings. Bulb colors indicate temperature ratings.

By acting fast, sprinkler heads help save lives and property by stopping fires early.

WATER MIST SYSTEM

Advanced Fire suppression with minimal water damage

A water mist system uses extremely fine droplets—smaller than 1,000 microns—to control, suppress, or extinguish fires. Unlike traditional sprinklers, it releases a mist under high or low pressure that rapidly absorbs heat, cools flames, and displaces oxygen around the fire.

This dual effect makes the system highly effective while reducing water damage, making it ideal for data centers, museums, hospitals, marine vessels, and industrial facilities.

Water mist systems are classified into low-, medium-, and high-pressure types, depending on droplet size and discharge pressure. They also reduce smoke and toxic gases, improving visibility and supporting safer evacuation.

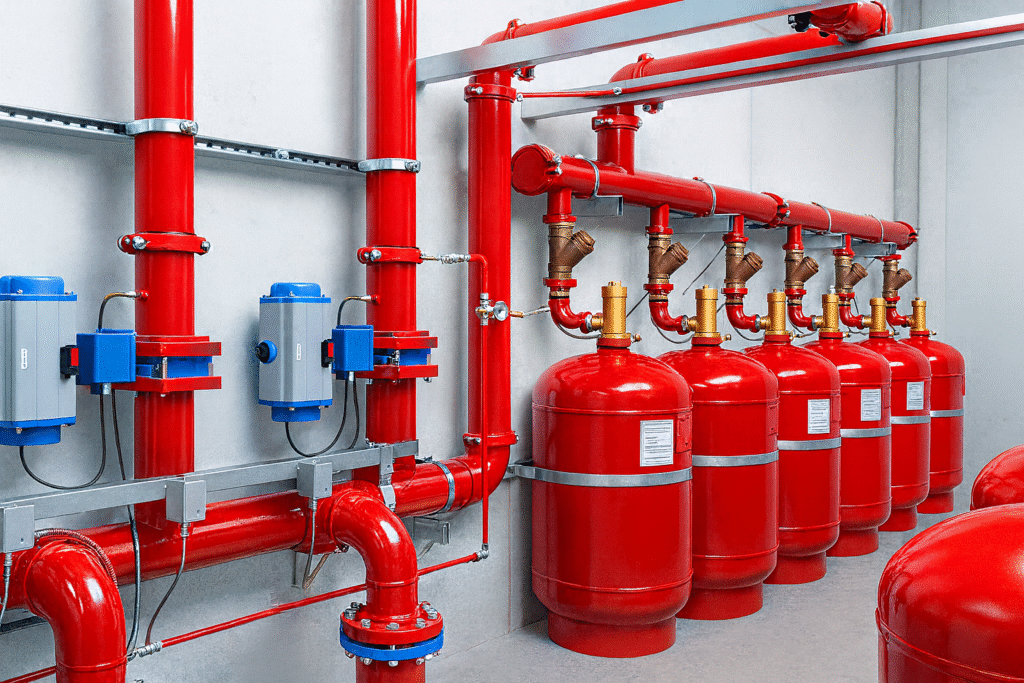

CLEAN AGENT SUPPRESSION

Fire protection without water or residue

A Clean Agent Suppression System uses electrically non-conductive, gaseous agents to extinguish fires without leaving residue or damaging sensitive equipment. Unlike water-based systems, it works by interrupting the combustion process and reducing heat, making it ideal for areas such as data centers, server rooms, control rooms, laboratories, museums, and medical facilities.

Common agents include FM-200, Novec 1230, and inert gas blends like IG-55, IG-541, nitrogen, or argon mixtures. These systems discharge within seconds to suppress fire quickly, while remaining safe for people due to their low toxicity.

Since they leave no residue, there is no cleanup required after activation, minimizing downtime and protecting valuable assets. The system is stored in high-pressure cylinders connected to a piping network with discharge nozzles, and can be activated automatically by a detection system or manually when needed.

Types include pendant (ceiling), upright (open ceilings), sidewall (wall-mounted), and concealed (aesthetic spaces). Quick-response heads are common in homes and schools, while standard-response types serve industrial settings. Bulb colors indicate temperature ratings. By acting fast, sprinkler heads help save lives and property by stopping fires early.

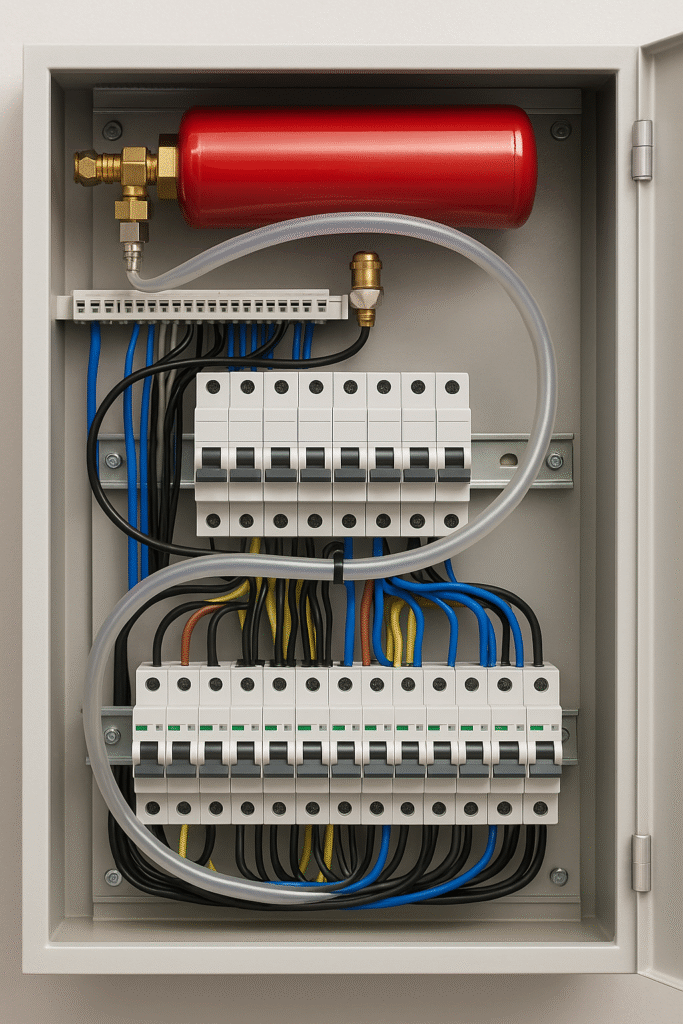

LOCAL APPLICATION SYSTEM

Targeted fire suppression for critical equipment

A local application system is designed to discharge extinguishing agents directly onto high-risk areas such as car engines, racks, and electrical cabinets. Instead of flooding the entire room, it focuses only on the protected equipment, reducing agent use and preventing unnecessary damage.

For car engines, the system delivers suppression inside the engine compartment. For racks, it protects concentrated equipment and cabling, while for electrical cabinets, it prevents fire from spreading within enclosed panels.

This focused approach provides rapid fire control, protects critical assets, and ensures minimal downtime.

hYBRID WATER MIST SYSTEM

Dual protection with mist and inert gas

A hybrid water mist system combines fine water mist with an inert gas, usually nitrogen, to suppress fires effectively. The nitrogen propels the mist at high velocity, allowing it to reach deep into enclosures or obstructed areas while also reducing oxygen to slow combustion.

The fine water droplets rapidly absorb heat, cooling flames and surrounding gases, while the gas component enhances suppression efficiency and reduces water use.

This makes hybrid systems especially effective for enclosed hazards such as turbines, machinery spaces, engine rooms, and data centers. By using both mist and gas, they provide fast flame knockdown, improved cooling, and minimal water damage compared to traditional systems.

kITCHEN WET CHEMICAL SYSTEM

Reliable Protection for High-Risk Commercial Kitchens

A kitchen wet chemical system is specially engineered to safeguard cooking areas where grease, oils, and fats pose a high fire risk. Using a potassium-based wet chemical agent, it discharges directly onto appliances, hoods, and ducts to quickly suppress flames.

Through a chemical reaction called saponification, the agent forms a protective soapy layer that cools surfaces and prevents re-ignition. Compact, fast-acting, and dependable, these systems are essential for restaurants, hotels, and industrial kitchens—providing superior protection where traditional sprinklers may fail.

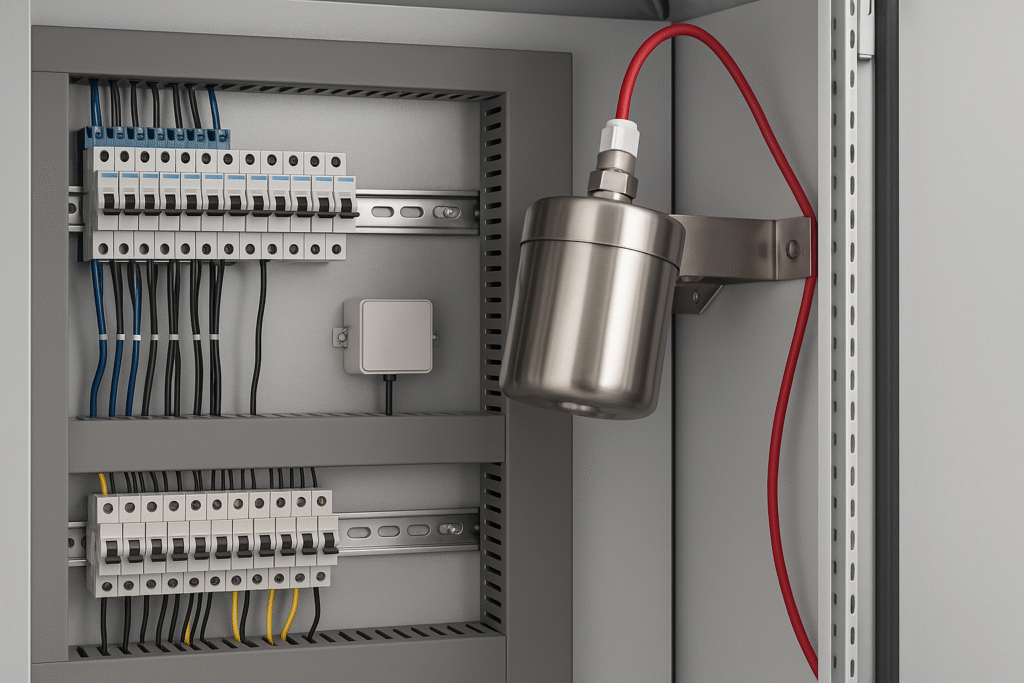

AEROSOL FIRE SYSTEM

Compact, residue-free fire protection

An aerosol fire suppression system extinguishes fires by releasing a fine aerosol of microscopic solid particles suspended in gas. When discharged, the aerosol interrupts the chemical chain reaction of combustion, quickly suppressing flames without water, leaving no residue, and requiring no piping network.

The suppression agent is stored in sealed generators that can be installed directly inside enclosures such as electrical panels, server racks, engine compartments, or storage rooms. This compact design makes aerosol systems easy to retrofit in both new and existing facilities.

Effective against Class A (solids), Class B (flammables), and Class C (electrical) fires, these systems are activated automatically by detectors or thermally triggered devices. They are valued for their small size, rapid response, low maintenance needs, and minimal cleanup, making them an excellent choice for protecting sensitive equipment and confined spaces.

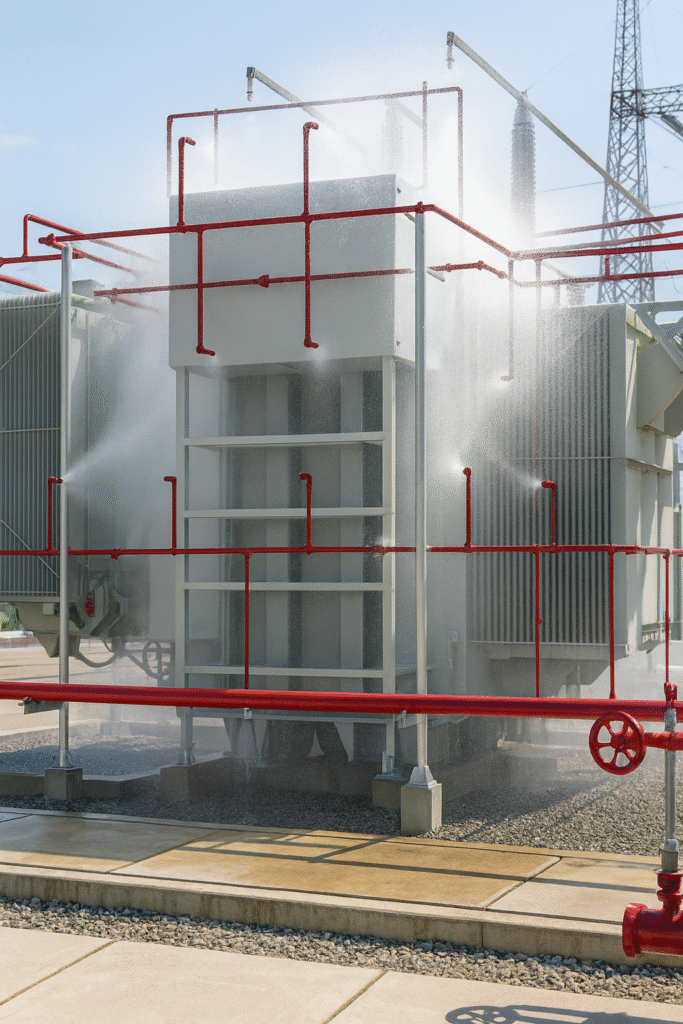

WATER SPRAY SYSTEM

Targeted High-Velocity Protection for Critical Equipment

A water spray system is a specialized fire protection solution designed to safeguard high-risk equipment and surfaces. Unlike general sprinklers, it delivers a directed, high-velocity water spray through purpose-built nozzles to provide localized coverage.

These systems are ideal for protecting transformers, storage tanks, conveyors, and turbine enclosures by cooling surfaces, suppressing flames, and preventing fire spread. Available in deluge mode (all nozzles discharge simultaneously) or automatic operation (triggered by detectors), water spray systems are essential in industrial facilities, petrochemical plants, and power stations where rapid cooling and surface protection are critical.

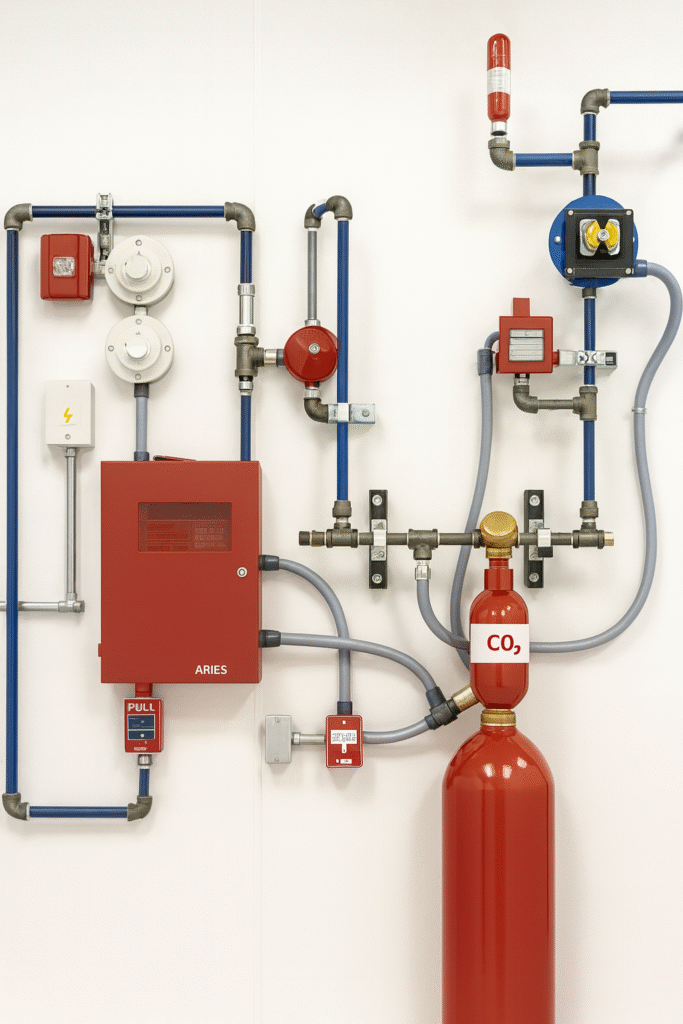

CO2 SUPPRESSION SYSTEM

Fast, Residue-Free Protection for High-Risk Environments

A CO₂ suppression system uses carbon dioxide gas to extinguish fires by reducing oxygen levels and cooling the hazard area. The gas is stored in high-pressure cylinders and released through a network of pipes and nozzles, quickly flooding the protected space or targeting specific equipment. Highly effective for flammable liquids, electrical panels, and industrial machinery, CO₂ systems are widely used in power plants, marine vessels, engine rooms, and manufacturing facilities.

Because CO₂ displaces oxygen, these systems are not safe for occupied areas—warning alarms and time delays are required before discharge. With no residue left behind, they minimize downtime while delivering fast, efficient suppression for critical operations.

FOAM SYSTEM

Advanced Protection for Flammable Liquid Hazards

A foam system is a fire suppression solution that combines water with a foam concentrate to form a thick foam blanket. This foam covers the fuel surface, cutting off oxygen supply, cooling the fire, and preventing flammable vapors from reigniting.

Foam systems are highly effective against Class B fires involving flammable and combustible liquids, making them widely used in aircraft hangars, fuel storage tanks, refineries, chemical plants, and warehouses. They can be designed as low-, medium-, or high-expansion systems and deployed through fixed piping networks, foam monitors, or foam chambers.

By delivering rapid surface coverage and effective cooling, foam fire suppression systems provide reliable protection for large liquid spill areas and high-hazard industrial environments.

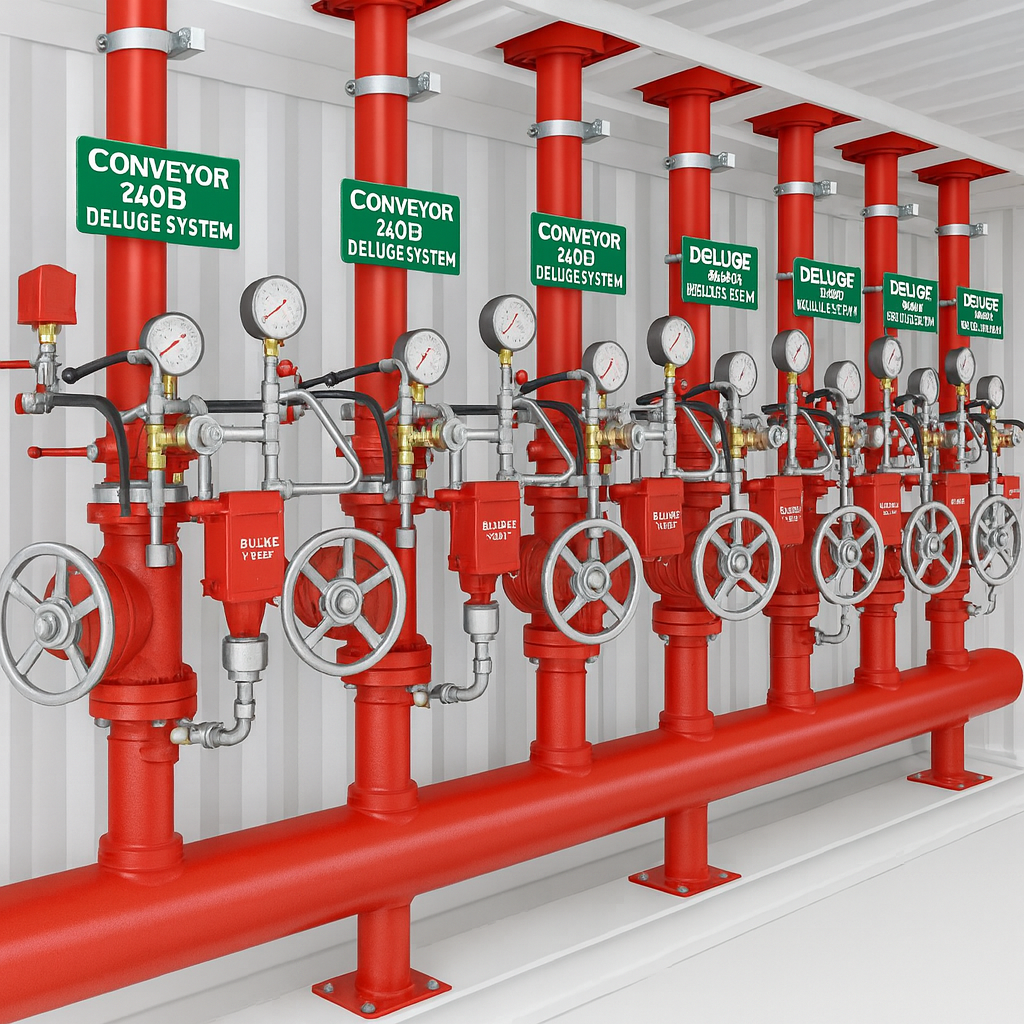

DELUGE SYSTEM

Rapid, Full-Area Water Discharge for High-Hazard Environments

A deluge system uses open sprinkler heads connected to a dry piping network that activates instantly during a fire. Once heat, smoke, or flame is detected, the deluge valve opens and water floods the entire network, discharging through all nozzles at once.

Unlike standard sprinklers that activate individually, a deluge system provides immediate, large-scale water coverage, making it ideal for high-risk sites such as aircraft hangars, chemical plants, power stations, and fuel storage areas. These systems are designed for cooling, fire suppression, and exposure protection in situations where a fast, total-area response is critical.

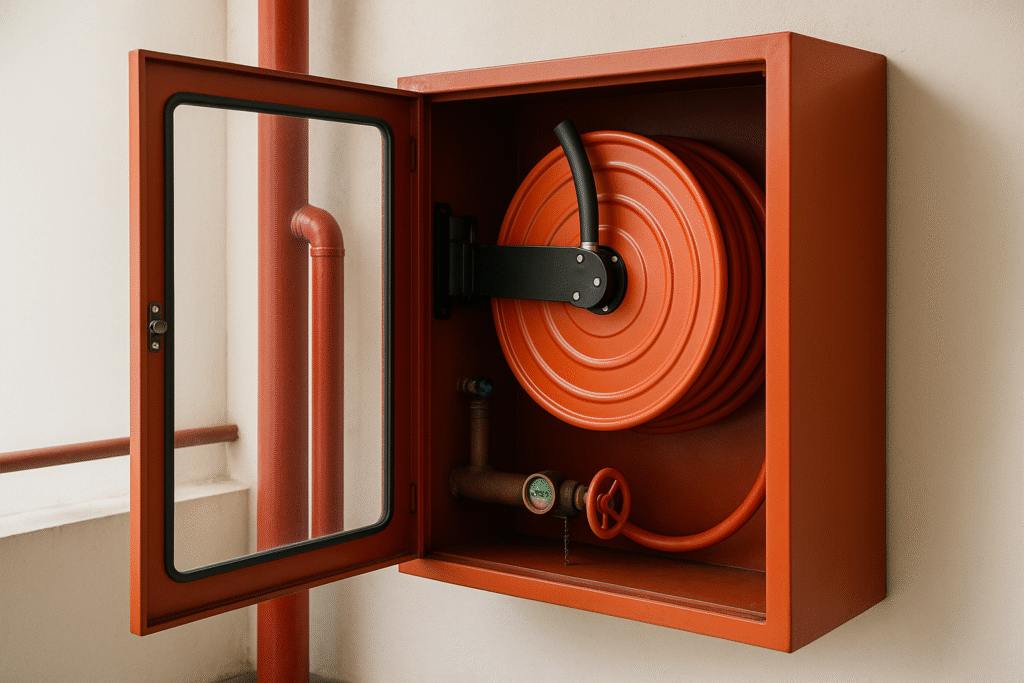

HOSE REEL SYSTEM

Advanced Protection for Flammable Liquid Hazards

A foam system is a fire suppression solution that combines water with a foam concentrate to form a thick foam blanket. This foam covers the fuel surface, cutting off oxygen supply, cooling the fire, and preventing flammable vapors from reigniting.

Foam systems are highly effective against Class B fires involving flammable and combustible liquids, making them widely used in aircraft hangars, fuel storage tanks, refineries, chemical plants, and warehouses. They can be designed as low-, medium-, or high-expansion systems and deployed through fixed piping networks, foam monitors, or foam chambers.

By delivering rapid surface coverage and effective cooling, foam fire suppression systems provide reliable protection for large liquid spill areas and high-hazard industrial environments.

VESDA Fire Suppression system

XXXXXXXXXXXXXXXXX

A VESDA Fire Suppression System uses Very Early Smoke Detection Apparatus to continuously sample the air and detect even the smallest traces of smoke at the earliest stage of a fire. This proactive detection allows for faster response, minimizing damage, disruption, and risk—making it ideal for mission-critical environments like data centers, clean rooms, and telecom facilities.